If your organization is considering getting a mobile health vehicle, you’ve probably thought about this question: Aluminum vs. wood—which is better for the build? This decision matters because the material you pick affects how durable your vehicle is, how much maintenance it needs, and how well it handles different environments.

Choosing the wrong option could have you spending more time and money on maintaining or even repairing your vehicle down the road. We know this choice can feel overwhelming, especially when you want your mobile clinic to serve your target community for years to come.

At AVAN Mobility, we’ve been designing and building mobile health vehicles for over a decade. Our mission is to break down barriers to healthcare and save lives with reliable, innovative vehicles. We’re proud of our expertise, but we also know we’re not the only company out there. That’s why we’re here to give you honest, clear information to help you make the best decision for your needs.

In this article, we’ll compare aluminum and wood in mobile clinic design and help you understand which material is a better fit for your mobile health unit.

Want to learn more about mobile medical units? Click the button below to check out our guide.

Why are the right materials so important in mobile health vehicles?

If your organization operates a mobile health vehicle in the U.S., you know that weather can vary a lot between states. In a state like Florida, you’ll typically experience more heat and humidity than in a state like North Dakota, where colder temperatures are more common.

This raises an important question: Does temperature affect the materials used to build your mobile health unit?

The short answer is yes. Temperature and weather conditions can impact the durability and longevity of the materials used in your vehicle. This is why finding a manufacturer that understands these challenges and uses the right materials in mobile health vehicles is so important. The right materials can help ensure that your mobile clinic remains:

- Functional, even in extreme weather

- Comfortable for patients and staff

- Durable, no matter where it operates

Choosing the right mobile health vehicle manufacturer that uses the right materials means your vehicle will be:

Durable: It should stand up to different weather conditions, from scorching heat to freezing cold.

Energy efficiency: The right materials can help maintain a comfortable temperature inside the unit, reducing the need for excessive heating or cooling.

Low maintenance: Materials that resist warping, rusting, or deteriorating will save you time and money on repairs.

Safe: The materials should contribute to a safe environment for both patients and healthcare providers.

Now that we’ve discussed the importance of material choice, let’s take a closer look at the use of wood in mobile health unit design.

What are the drawbacks of using wood in mobile health vehicles?

When it comes to manufacturing mobile health vehicles, using wood can cause some real headaches down the road. Here’s why:

Moisture problems: Wood tends to soak up moisture, which can lead to warping, rotting, and even mold. This can be a big issue if your vehicle operates in humid or rainy areas.

Heavy weight: Wood is heavier than other materials, like aluminum. This extra weight means your vehicle could end up costing more to run because heavier vehicles use more fuel.

Fire risk: Wood is flammable, which is a safety concern in any vehicle, especially one meant to serve as a mobile health unit. The last thing you want is to worry about fire hazards.

High maintenance: Wood can break down over time and isn’t as durable as other materials. This lack of durability can lead to costly replacements sooner than expected.

Pest issues: Wood is also prone to damage from pests like termites, which can weaken the structure and cause further problems.

Considering all these drawbacks, wood isn’t the best choice if you’re looking for a durable, safe, and low-maintenance mobile health vehicle.

While wood is generally cheaper than aluminum for mobile medical vehicle construction, aluminum offers too many advantages that justify its higher price,

Next, let’s explore why aluminum is a more suitable option for mobile health vehicles.

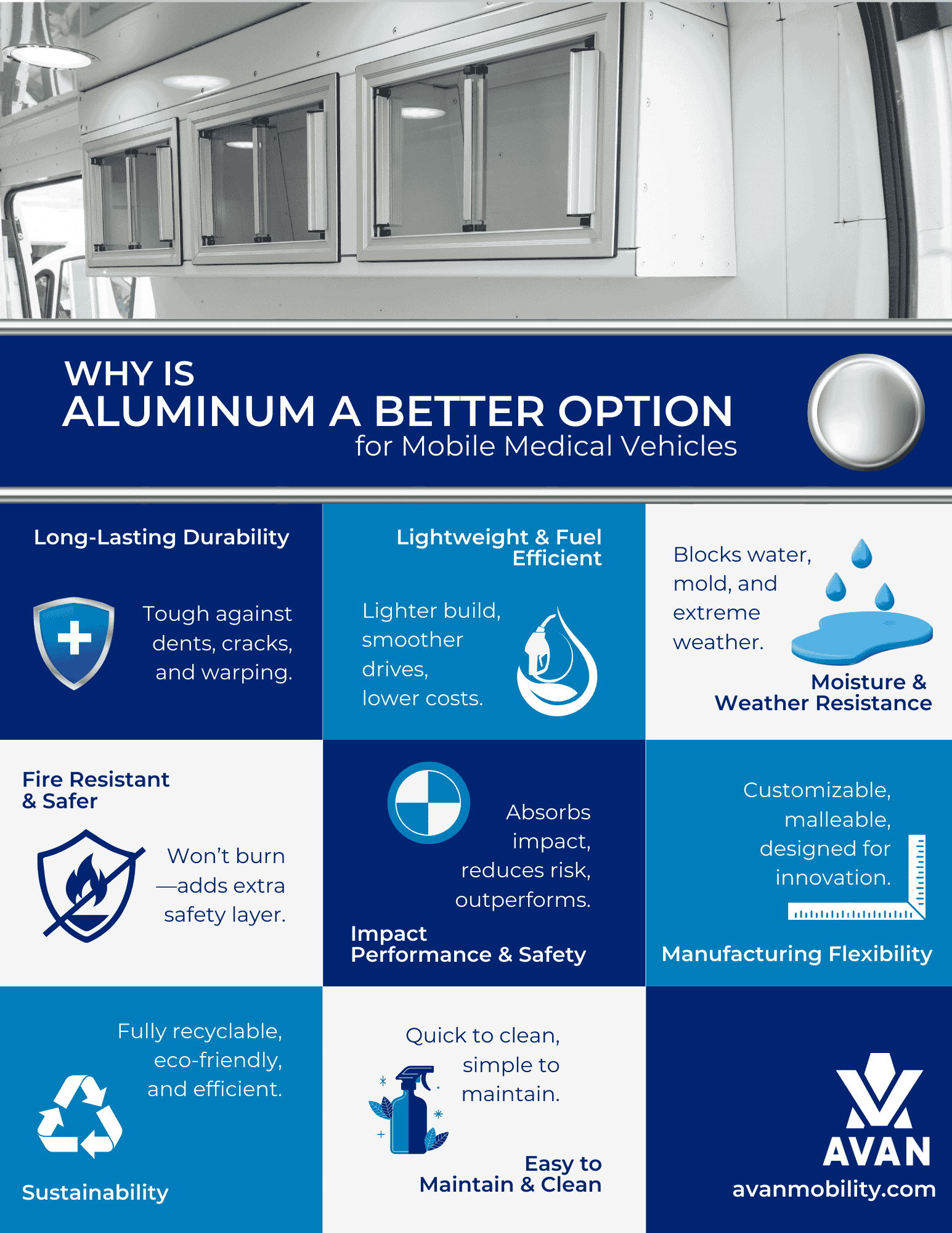

What are the benefits of using aluminum in mobile health vehicles?

Aluminum is a popular choice of material in manufacturing mobile health vehicles, and for good reason. Let’s dive into why aluminum might be the better material for your mobile health unit:

Durability: Aluminum is far more durable than wood. It can withstand the wear and tear that comes with being on the road, and it’s much less likely to suffer from moisture or impact damage. This means your vehicle will last longer and perform better in various conditions.

Lightweight: Despite its strength, aluminum is a lightweight material. This makes your mobile health vehicle easier to drive and more fuel-efficient, saving you money on operating costs.

Moisture resistance: Unlike wood, aluminum doesn’t absorb moisture, so you won’t have to worry about issues like warping, rotting, or mold. This is a huge plus if your vehicle operates in wet or humid environments.

Easy to clean: No one wants to be in a dirty healthcare environment. Aluminum surfaces are easier to clean and disinfect, helping to maintain a sanitary environment for patients and staff. This is particularly important in a mobile clinic, where hygiene standards must be maintained.

Low maintenance: Aluminum requires much less upkeep compared to wood. It doesn’t break down as easily, meaning fewer repairs and less downtime for your vehicle.

Safety: Aluminum is non-flammable, making it a safer choice for a mobile health vehicle. You won’t have to worry about the material contributing to fire hazards.

Choosing a manufacturer that uses aluminum material for your mobile health vehicle design can provide peace of mind, knowing that your vehicle is built to last, easy to maintain, and safe for everyone involved.

Aluminum vs. wood: head-to-head comparison

Take a look at the table below for a head-to-head comparison between aluminum and wood materials used in the automotive industry. Keep in mind that MPa stands for megapascal, a unit of pressure or stress in the metric system that’s used to measure the strength of materials.

| Criteria | Aluminum | Wood |

| Tensile strength | 150-400 MPa | 40-80 MPa |

| Weight efficiency | High (light & strong) | Medium (light but less rigid) |

| Corrosion resistance | Excellent (oxide layer) | Poor (rot, decay) |

| Impact performance | Predictable deformation (crumple zones) | Brittle (splintering) |

| Manufacturing flexibility | High (weldable, malleable) | Limited |

| Sustainability | Fully recyclable | Renewable but high-maintenance |

Choose the right material for your mobile health vehicle

You came here wondering whether aluminum or wood is the better choice for building your mobile health vehicle. Now that you’ve made it this far, you’ve seen the downsides of using wood and learned why aluminum stands out as the more beneficial option for mobile clinic design.

At AVAN Mobility, we know that the right materials make all the difference. That’s why we use aluminum in our builds—it’s durable, lightweight, and easy to maintain, making it perfect for the tough demands of mobile healthcare.

We’re all about creating vehicles that last, perform well, and help you bring healthcare to those who need it most. We’re proud to be leaders in this space, and we’re here to make sure your mobile health unit is built to the highest standards.

If you have any questions or need advice on designing your mobile health vehicle, just click the button below to chat with one of our mobility experts. We’re here to help you every step of the way.

And if you’re not quite ready to talk, no worries! Check out some of our other resources to learn more.

Start with checking out our article on some of the equipment that can be installed in a mobile clinic.

After that, read our article on the cost of a mobile medical unit. It will give you a better idea of what you can expect to pay for one of these vehicles.

FAQ

Q: Why is aluminum better than wood for mobile health vehicles?

A: Aluminum is more durable, lightweight, and resistant to moisture than wood. It’s also easier to maintain and ideal for healthcare settings.

Q: How does aluminum handle extreme weather conditions?

A: Aluminum withstands extreme temperatures without warping or deteriorating. It’s highly resistant to both heat and cold, making it reliable in any climate.

Q: Can aluminum be customized for different mobile health needs?

A: Yes, aluminum is highly versatile and can be easily customized to fit various designs and specifications for mobile health vehicles. This flexibility allows for tailored solutions that meet your specific needs.